Our production departments’ personnel, whom operate within the frame of Quality Policy brought to us by Quality Management Systems, also work meticulously to ensure national and international satisfaction while meeting customers’ needs and expectations on site and on time.

Raw Material

We have different quality and sizes of raw materials in our stock as metal sheet and they are round and rolled shaped for us to be solution partner in fast delivery to our customers. Chemical compounds of entire raw materials which we purchase and obtain from our suppliers are verified with our own spectrometer. Traceability of raw materials that pass all tests concerning size and chemicals are established with barcode system.

Tooling

Toolings used by us for pressing are also manufactured by us through blending our many years of experience in this industry and our accumulated knowledge. We realize designing, determining life and maintenance of our moldings, which affect the product quality directly as known together with our qualified personnel and universal milling machines and lathe workbench, with great care.

Press

Together with support of our presses and experience brought on by years and accumulated knowledge we offer supremacy of press manufacturing at capacities varying between 1 to 325 tons in the pressing room section of our factory.

Threading

Threading , rubbing and scrubbing can be performed in line with customers’ requirements with our drills.

Welding

Welding process is performed in compliance with the standards of ISO 3834-2. All our welders have Welding Competency Certificate in order to determine welding capabilities of the manufacturer who is going to manufacture at a quality indicated and quality requirements for welding concerned production in our factory / plant.

Machining

Genç Rondela possesses a machining line equipped with state-of-art technology for manufactured product groups. There are various models of CNC workbenches, C-axis CNC workbenches, multi-axis CNC workbenches and a special centreless CNC grinding machine in the machining department in the company. The department is capable of meeting customers’ needs flawlessly with the exclusive staff and powerful machinery.

CNC Saw

All round raw materials which are to be processed and threated in CNC machines are delicately and rapidly cut with CNC saws into any size desired.

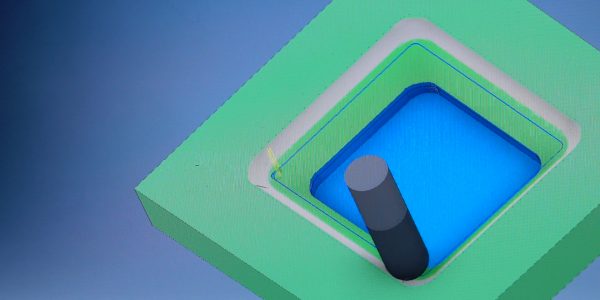

CNC Vertical Milling Centre

With CNC 4 axis Vertical Milling Centre we can process / treat our molds under our own roof.

CNC Turning

Genç Rondela owns a new metal cutting / machining line equipped with new technology for product groups it manufactured. Inside the metal cutting /machining section / department which is located under its own roof ; there are Cnc lathe workbenches, C axis lathe workbenches, multi-axis cnc lathe workbenches and also a Cnc rotor grinding machine without special centerless. Together with its distinguished department staff and powerful machinery it responds to customer demands completely.

Deburring

We apply the process which we call deburring to our products to increase the quality of product and respond to special demands of our customers. We perfectly performe surface process with the vibration and centrifuge machines found in this section / department.

Plating

Meeting demands completely.

We can complete zinc plated, phosphate plated and galvanized demands of our customers in our plating facilities found under our own roof.

Hot-dip Galvanized

Zinc Plated

Phosphate Plated

Packaging

With our raw material and finished product stock; we are capable of offering the opportunity of “just in time” in our shipping and deliveries to our customers. We are capable of applying branding and protective packaging methods if desired to manufactured parts.

Logistics

We work as solution partner in fast deliver to our customers. Through customized storage to customer we ensure customer satisfaction and products can be at any desired location on any desired date.

Türkçe

Türkçe Deutsch

Deutsch